Automated Vertical Lift Modules (VLMs)

Get the Most Performance Out of Every Inch of Your Manufacturing & Warehousing Floor Space with Modula’s Vertical Lift Modules (VLM)

Experience the Most Advanced Material Automation with VLMs

Made in the USA and partnered with Bradford Systems as an authorized dealer, Modula produces automated storage systems using the most advanced Vertical Lift Module (VLM) and vertical lift technology in the industry. Their innovative solutions include Automated Storage and Retrieval Systems (ASRS) meant to streamline your warehouse your workflow, increase efficiency, and enhance safety while ultimately increasing your bottom line.

- Saves Space & Reduces Operations Cost: Saves up to 90% of valuable floor space compared to traditional storage methods.

- Increases Productivity and Accuracy: Vertical lift modules automatically deliver items to the operator with a simple touch on the Copilot console or a scan of a barcode.

- Process More Orders in Less Time: Increase productivity up to 85%. One worker is able to handle the same volume previously performed by multiple operators.

Connect with Bradford Systems

Fill in below form as complete as possible and one of our representative will be in touch with you shortly

Reimagine Material Handling with Modula's Innovative VLMs

As a proud partner of Modula, we’ll work with them to customize ASRS and industrial vertical storage solutions specific to your unique warehouse or workspace needs. Able to place and retrieve goods from securely stored locations, these ASRS are the best solution for organizing inventory, especially if you’re dealing with high volumes.

If your warehouse is feeling cramped, inefficient, and you can’t quite find the space you need, Modula’s VLMs are the perfect choice. Browse VLM software, picking solutions, and accessories to make the most of your system.

Ready to increase safety and efficiency in your Warehouse or Plant?

Modula Storage Systems are proudly made in the USA. What that means is while our competitors need 5-6 months for delivery, we can deliver a VLM just 90 days after the order date!

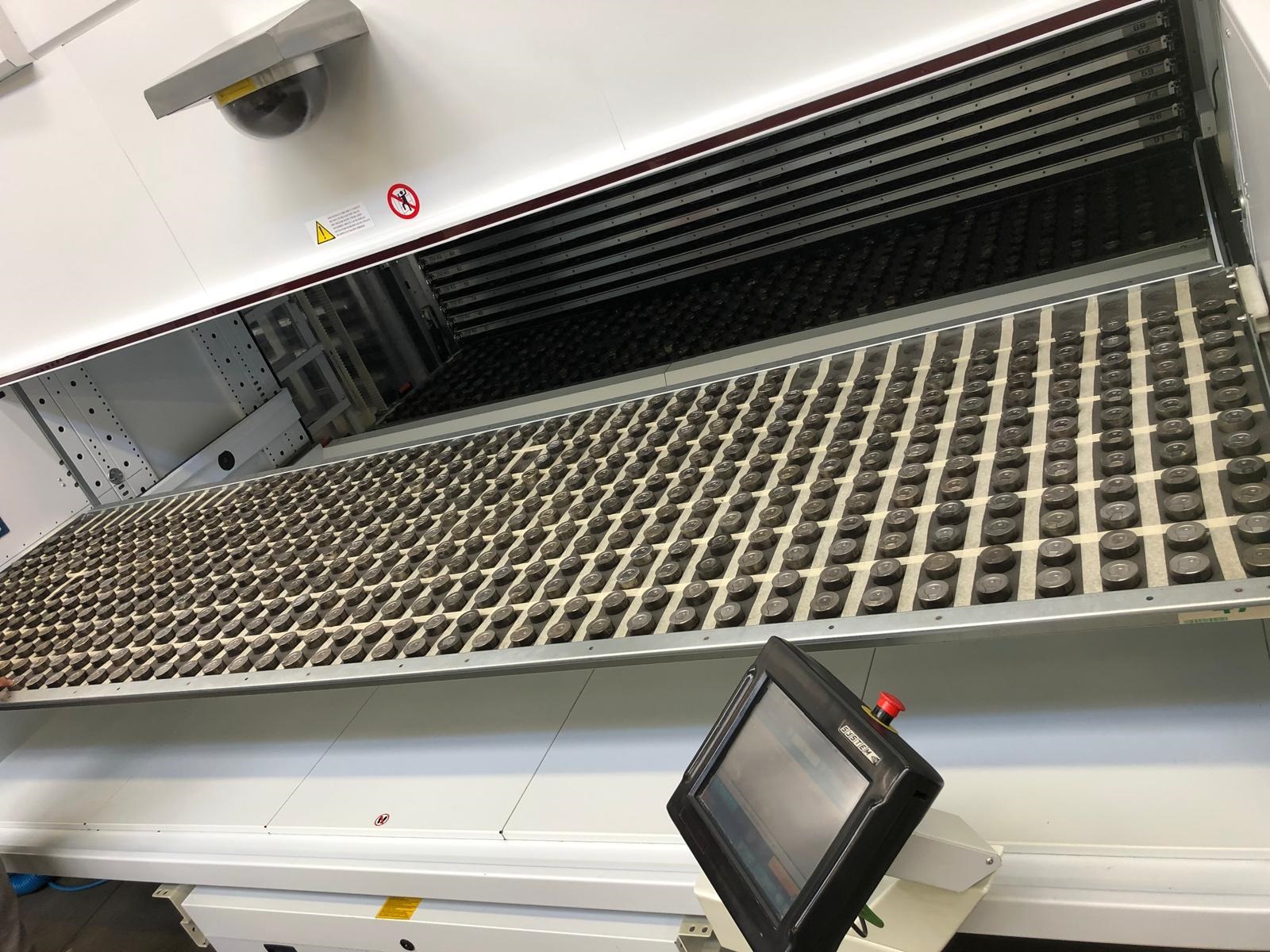

With a throughput of up to 130 trays per hour and a tray payload capacity of up to 2,200 lbs, Modula Lift is a workhorse of a machine. Watch this video to see it in action. Discover the variety of Modula products below and contact us to get started.

Modula Vertical Storage Solutions

Modula LIFT

Available in a wide range of sizes and capacities, the Lift is used by businesses everywhere to modernize operations.

Modula SLIM

Modula Slim is the perfect choice for smaller settings in which floor space is at a premium…

Modula Next

Modula Next is an innovative automated storage and retrieval solution that operates on a goods-to-person principle.

Modula Flexibox

Processing up to 180 bins per hour, Modula Flexibox is the smart solution for fast-moving industries.

Innovative Warehouse Storage Solutions – For Every Operational Need

Considering all your warehouse needs and storage solutions can be daunting. Many facilities need to accommodate both large equipment as well as smaller tools, materials and parts. Beyond storage, your employees need to be able to access and retrieve stored items quickly and easily in order to stay productive, efficient and safe.

Optimizing your warehouse space doesn’t have to be an overwhelming endeavor. With Modula VLM LIFT and SLIM systems, we can customize and install high-density shelving to maximize your space beyond what you can imagine. Available in a wide range of sizes and capacities, Modula VLMs are the ideal storage solution for any operational need.

Modula's Vertical Lift Modules in Action

Available in a wide range of sizes and capacities, Modula VLMs are the ideal storage solution for any operational need. Browse the videos below to see these automated VLM offerings in use:

Modula Lift

Modula Slim

Modula Next

Modula Flexibox

Vertical Lift Modules Features & Benefits

These automated vertical storage systems take up a minimum footprint by utilizing the ceiling height. Ideal for storing industrial products, components and spare parts, Modula vertical lifts have helped companies improve their workflow processes.

- Reduce the Risk of Injuries: By eliminating the stress and strain of reaching high and low, VLMs help employees stay safe on the job.

- Improve Efficiency and Save Time: Workers aren’t scrambling around a huge warehouse trying to locate items.

- Flexible Integration & Scalable Design: Trays can be organized for every type/size of stored item. Configurations can be adjusted to accommodate changes in the size or quantity of items.

- Ease Operational Effort with the Copilot Console: The console simplifies materials management, both in retrieving and replenishing items.

Modula Warehouse Management Systems

Modula Warehouse Management System (WMS) is a complete inventory management software, designed to operate Modula’s automated storage and retrieval solutions or as a stand-alone software in traditional warehouses (manual areas).

- Pre-configured to readily integrate with your ERP or DMS

- User-friendly interfaces and short training times

- Complete visibility into inventory and operations, down to a single tray

- Expandable to grow with your business as needed

Versatile Industry Applications

View Modula case studies to experience the innovative time and space saving industrial storage systems that are ideal for a wide range of markets.

Aluminum

Automotive

Beverage

Ceramics

Distribution

Electrical & Electronics

Fragrance & Perfume

Hydraulic

Mechanical

Paper & Publishing

Pharmaceutical

Plastic

Steel

Our Experts Will Solve Your Storage Problems

Modula Vertical Storage – FAQs

Modula is a brand of vertical lift modules (VLMs) that automatically deliver stored items to an ergonomic access point.

Trays are stored vertically and retrieved by an automated lift when requested. Operators access items at waist height.

Trays can support hundreds of pounds, with total unit capacity reaching tens of thousands of pounds.

Distribution centers, manufacturing plants, automotive parts departments, and hospitals.

Yes. Modula systems integrate with WMS, ERP, and barcoding/RFID systems for full inventory control.

Light curtains, access restrictions, and emergency stops, among other safety options, ensure operator safety