Attabotics

The leading supplier of storage solutions in any industry providing shelving, lockers, casework & everything in between.

Attabotics 3D Cubic Storage System

Save space and time with 3D cubic storage technology.

Attabotics is an Automated Storage and Retrieval System (ASRS) company offering a 3D robotic fulfilment solution tailored for modern commerce. This solution is unique in its design, which draws inspiration from nature.

Built to address the supply chain and fulfilment problems of today and in the future, the Attabotics system is optimized for the three-dimensional movement of robotic shuttles within its storage structure. The system’s patented storage structure matrix and 3D robotic shuttles, also known as the Studio, allows companies to significantly improve productivity levels while materially reducing space and labor requirements by maximizing vertical space.

Get in Touch for a Free Quote

Fill in below form as complete as possible and one of our representative will be in touch with you shortly

"*" indicates required fields

How It Works?

The Attabotics system, also known as the Studio, is made up of 5 components. These include robots, workstations, storage grid, software, and bins, which can be added and customized to your unique needs. The robots move within the system in three dimensions to store and retrieve the goods that are stored in bins in a matrix pattern.

Because of the nature of this design, the robots have direct access to every bin within the system, allowing for faster retrieval times and no need for bin reslotting. Bins are automatically sequenced and presented to operators for picking.

Value Props

Attabotics maximizes efficiency by allowing you to pick, pack, and ship in one unified workflow. Features like automatic sequencing and sortation and direct robot access to every item in the system allow for process optimization before the product even reaches operators.

Supplementary stat: Direct access to any storage location in less than 90 seconds.

The dense design of the Studio fits into almost any warehouse, reducing your fulfilment space by up to 85%. This enables you to make room for more services and products, redirect your employees to other tasks, and ultimately enhances your brand’s value proposition.

Supplementary stat:

- Up to 85% reduction in space.

- 4-5x your storage capacity.

Each component of the Studio acts as a building block for your future warehouse. Expand the grid, adapt the software, and seamlessly add robots and workstations, scaling and customizing your system to meet tomorrow’s challenges, today.

Keep up with the demands of single item orders and same day shipping by boosting efficiencies at points of friction in the fulfilment process. This includes powerful workflow software that allows for the system to seamlessly prioritize rush orders without manual intervention.

Responding to the need for a more sustainable supply chain, the Attabotics system is designed to reduce the overall climate impact of storage. This means less warehouse space to climate control, less power to keep things flowing, and less time for idling trucks.

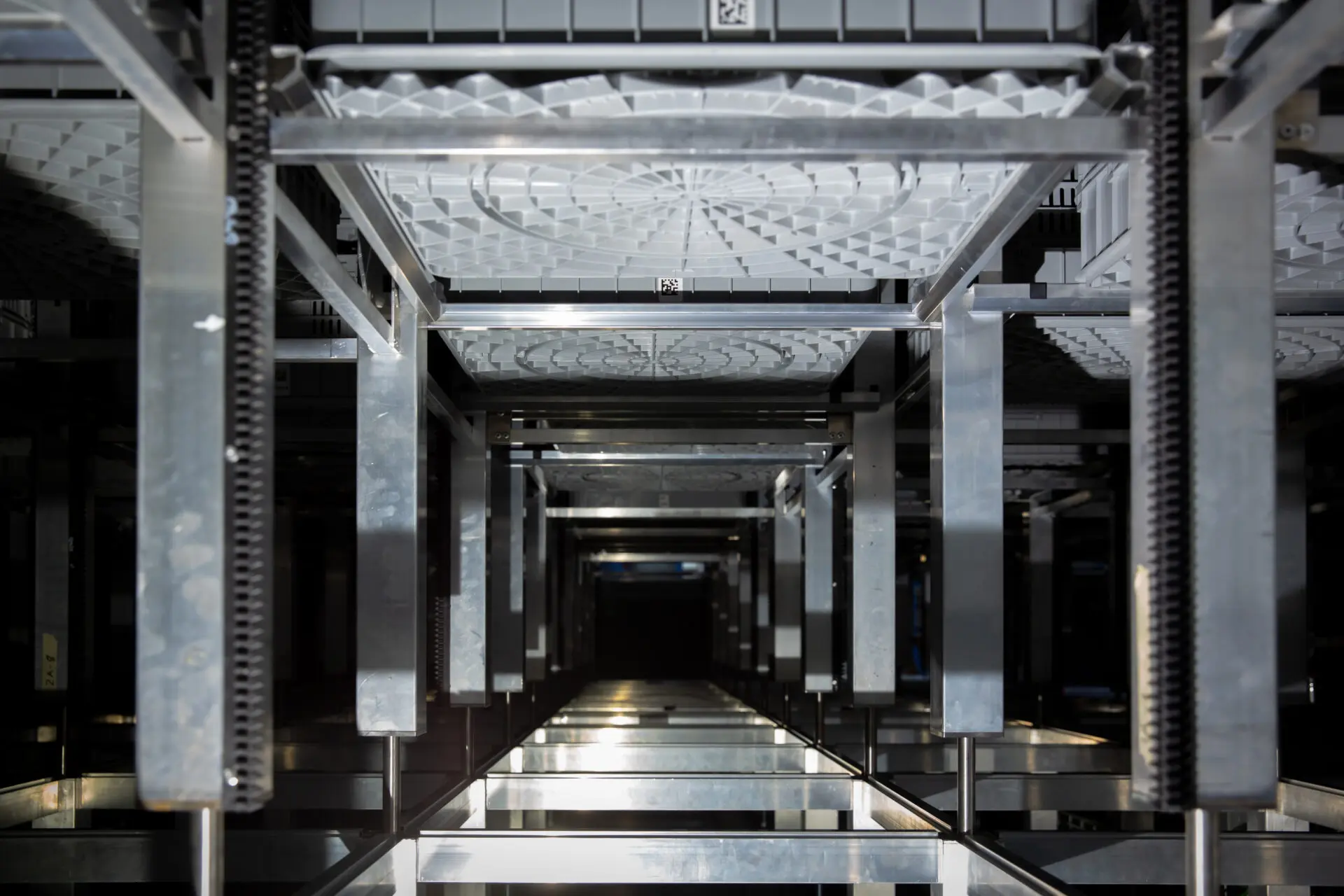

The Cubic Storage System

The structural and modular architecture of our cubic storage system, also known as the Studio, makes it scalable to almost any size and need, with state-of-the-art software that is augmentable by design and gives you continuous real-time updates. The proprietary robots move and pick in three dimensions to increase efficiency, flexibility, and warehouse performance.

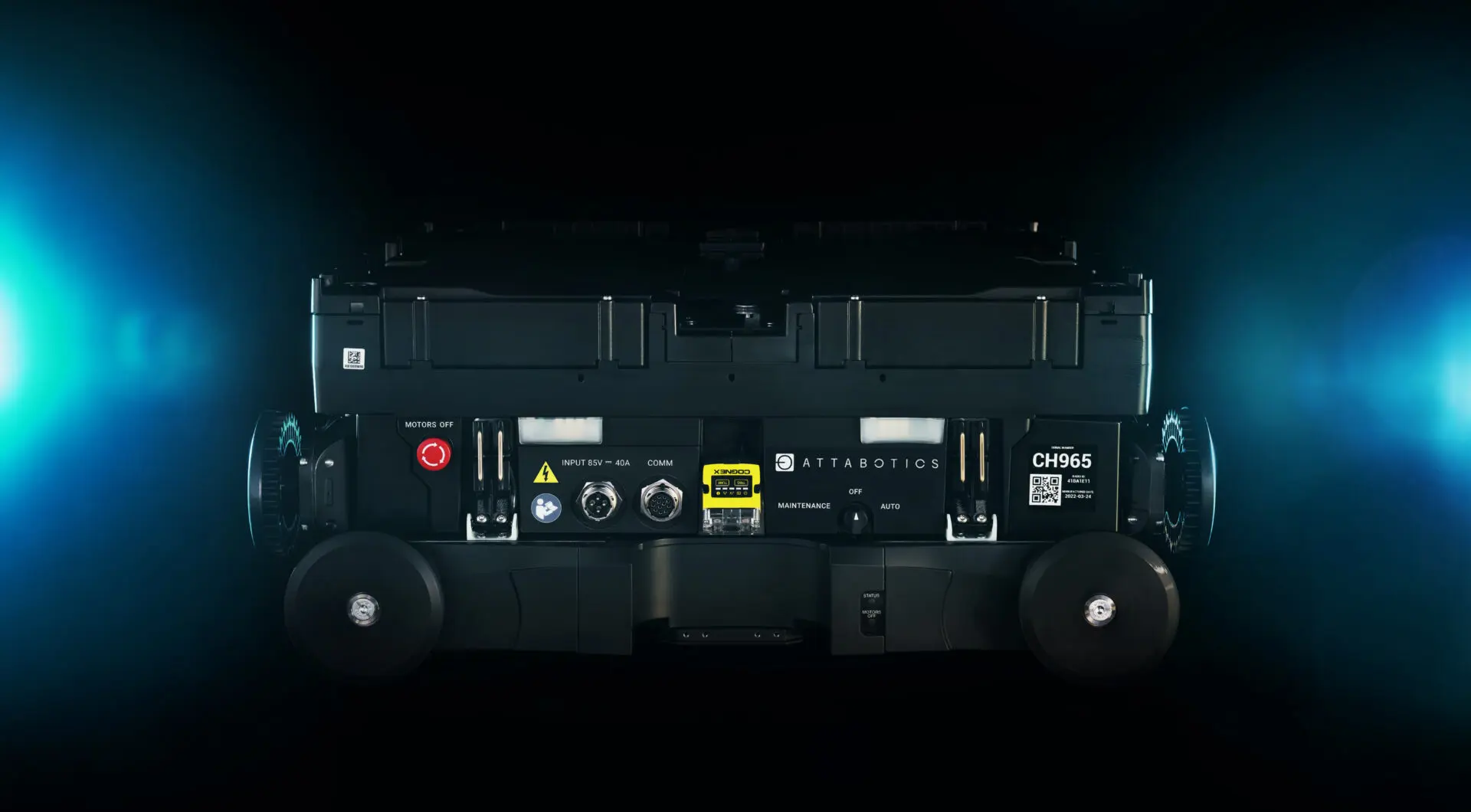

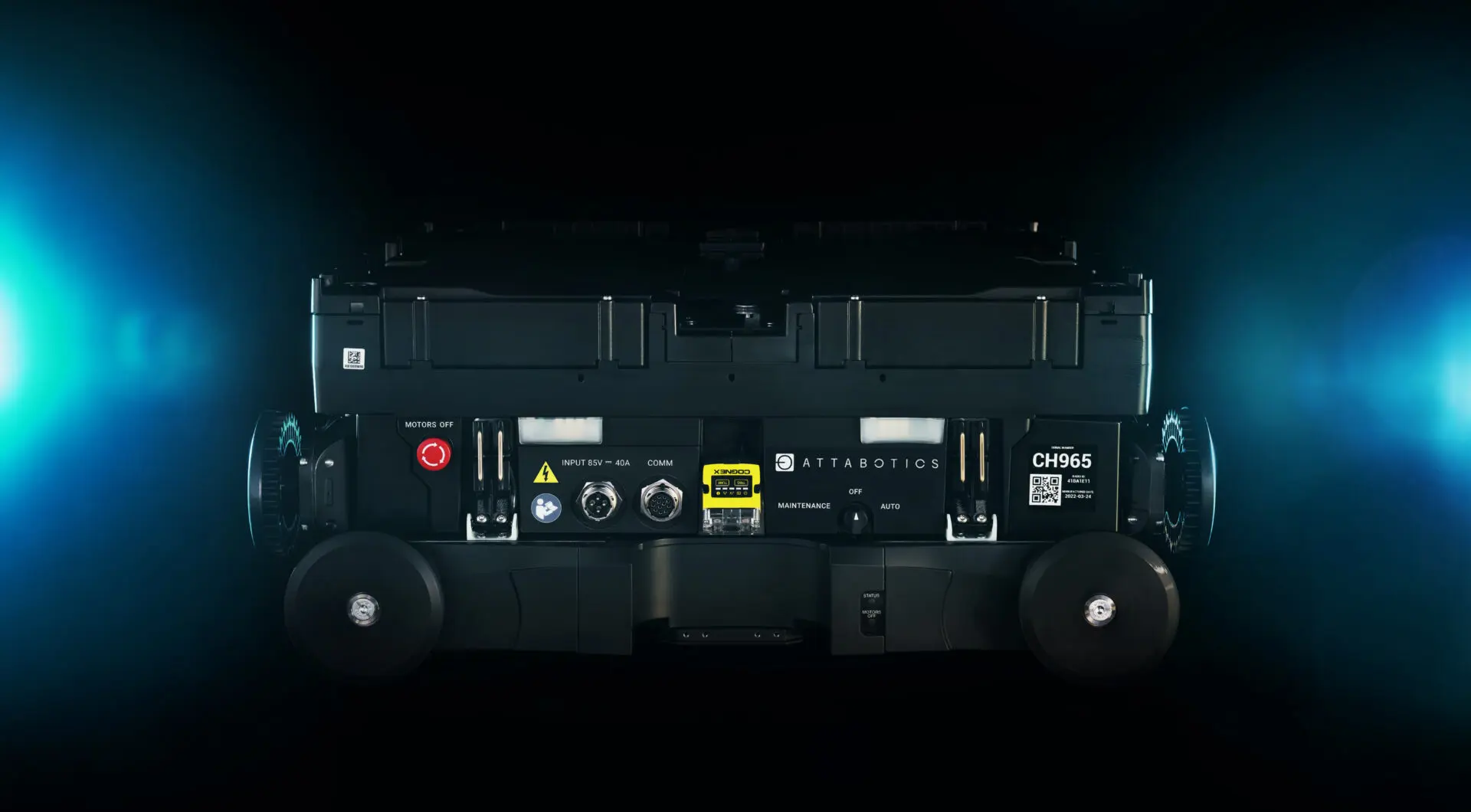

Robots

The Attabot™ is the pulse of your future warehouse, rapidly moving in three dimensions throughout the structure to directly access your valuable goods. Embracing the spirit of innovation from automation technology but evolving it to meet the needs of tomorrow, the Attabot™ is ushering in the new era of commerce.

Storage Grids

The grid is the foundation of the structure. Its proprietary matrix design allows for robots to navigate in three dimensions, with direct access to storage bins. As with any good foundation, the grid is built to be strong and dense, but it also allows for flexibility and adaptability.

Workstations

This next-generation workstation improves on a proven design while optimizing for efficiency by reducing points of friction in the human-machine experience. With enhanced safety features, an ergonomic design, a faster presentation speed, and a lower footprint, the new Node X is redefining the way we work.

Weave Software

Weave is the order management and control solution to efficiently manage the movement of robots and fulfillment of orders. It is optimized for the three-dimensional design of the Gallery, enabling the Attabots™ to route for faster throughput and less downtime. Weave is designed to grow with your ambitions, connecting new fulfillment spaces as you move closer to your customers.

Gordon Food Service Calgary

Gordon Food Service Calgary needed to upgrade its storage and picking processes to meet rising customer demands. They partnered with Attabotics to implement an automated storage and retrieval system (ASRS) that integrated with their existing manual operations.

This collaboration significantly increased order fulfillment efficiency, with minimal downtime during the transition. Since 2018, the partnership has resulted in a 2X increase in throughput efficiency, providing stability and improved performance, especially during peak demand periods.

SCI: Logistics & Supply Chain

SCI faced increasing e-commerce volumes, labor challenges, and rising real estate costs. To address these issues, they partnered with Attabotics to implement a goods-to-person (GTP) automation system. This next-generation ASRS solution significantly improved productivity, increasing units picked per hour by 65% and reducing warehouse space by 70%. The partnership enhanced efficiency, ergonomics, and pick accuracy. Attabotics’ 3D robotic system maximized SCI’s existing space, providing a valuable automation solution and greatly improving order efficiency.

Frequently Asked Questions

No. The Attabotics system is designed to suit your building including working around walls, corners, and consuming existing building columns inside the structure to allow maximum storage density within a facility.

Attabotics systems can be built up to 9 meters (29 feet 6 inches). The systems need another ~5 feet above the structure for clearance.

Yes, the Attabotics workstations can be used for picking, decanting, cycle counts, and kitting. These functions are available at each workstation by selecting the mode through the HMI.

Keep up with the demands of single item orders and same day shipping by boosting efficiencies at points of friction in the fulfilment process. This includes powerful workflow software that allows for the system to seamlessly prioritize rush orders without manual intervention.

No, all maintenance is done at ground level through robot maintenance bays.

No, AttabotsTM charge using supercapacitors while inside the Gallery – charging while at work.